Expo puts futuristic rail transit on fast track

Intelligent maintenance helmet, energy-storage modern tram, transformer substation inspection robot...The 2019 China International Rail Transit and Equipment Manufacturing Industry Expo that closed Sunday in the central Chinese city of Changsha, capital of Hunan Province, brought to us some of the latest products that are faster, greener and smarter.

With its large transport capacity, safety and ever-increasing speed, rail transit has regained its popularity in China and elsewhere in recent years.

The 2019 China International Rail Transit and Equipment Manufacturing Industry Expo that closed Sunday in the central Chinese city of Changsha, capital of Hunan Province, brought to us some of the latest products that are faster, greener and smarter.

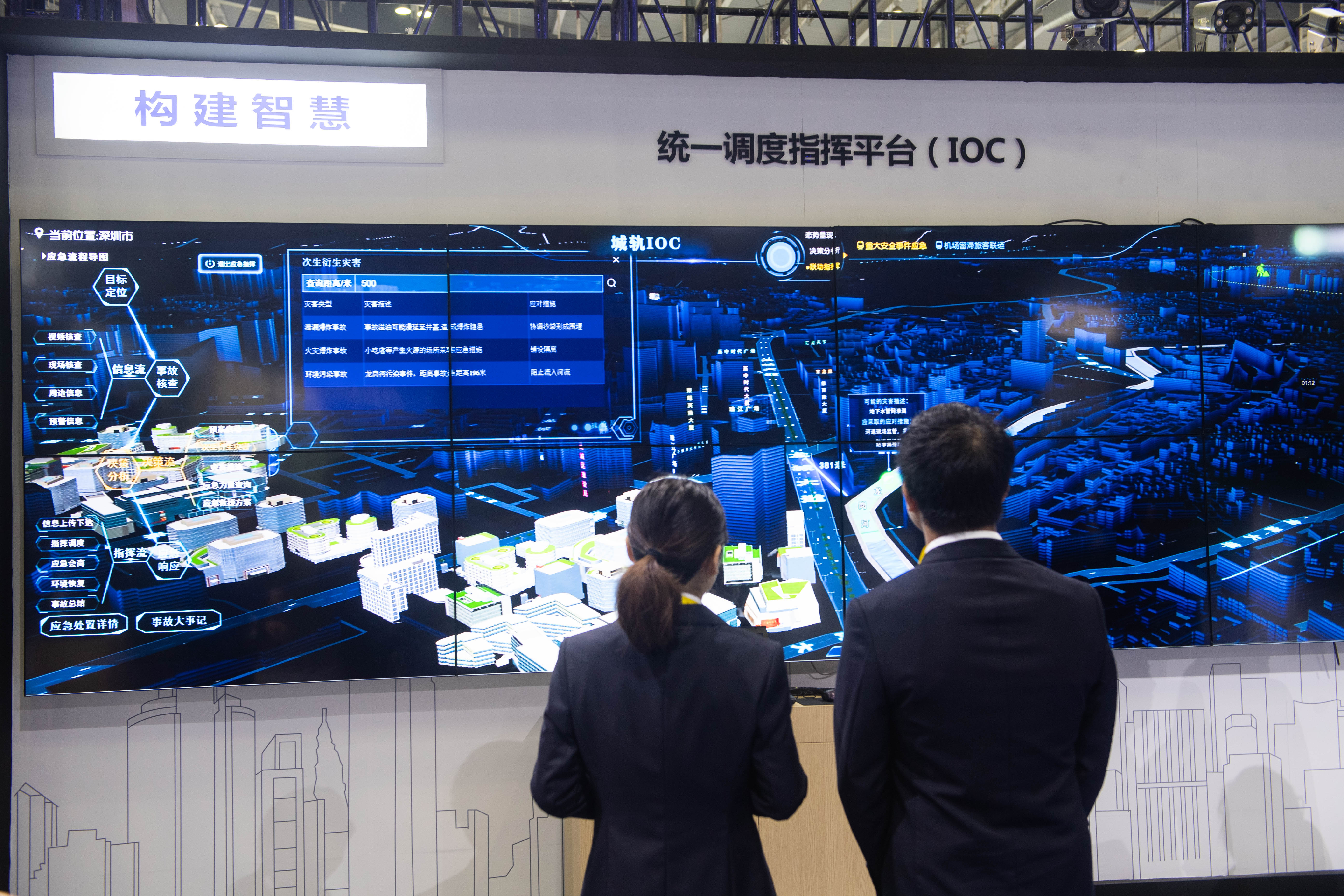

A Huawei urban rail cloud platform is on display at the 2019 China International Rail Transit and Equipment Manufacturing Industry Expo in Changsha, central China's Hunan Province, Oct. 18, 2019. [Photo/Xinhua]

At the exhibition, an intelligent maintenance helmet independently developed by Changsha Metro Group made its debut.

The helmet has communication functions, and can automatically identify equipment and personnel and greatly improve the efficiency.

As the stations, train sections and control centers all have their own systems, collaborative work is difficult to achieve and data cannot be shared efficiently. These problems have prevented a more efficient and intelligent management of the metro and other urban railway systems.

Huawei's urban rail cloud platform offers a solution to operators.

With the support of technologies including the Internet of Things, big data, artificial intelligence and integrated communications providers, the platform can gather and process the rich data for various application scenarios, such as face-scanning check-in, precise passenger flow prediction, one-touch opening and shutdown of stations and intelligent site management.

The maximum operating speed of the energy-storage modern tram, which was launched by CRRC Zhuzhou Locomotive company, is about 70 km per hour. The tram, powered by ultracapacitors, can be quickly recharged within 30 seconds when the tram stops to pick up and drop off passengers.

The CJ6 intercity EMU train manufactured by CRRC Zhuzhou Locomotive Co., Ltd. is exhibited at the 2019 China International Rail Transit and Equipment Manufacturing Industry Expo in Changsha, central China's Hunan Province, Oct. 18, 2019. [Photo/Xinhua]

The tram can travel 5 km after each 30-second charge. It can also recover the energy used in braking.

China boasts vast territory, complicated terrain and diverse climate, which has motivated the country's rail equipment manufacturers to constantly seek innovations.

A transformer substation inspection robot that can perform well in 30 degrees Celsius below zero attracted the attention of many visitors.

The robot can achieve unmanned operation and is adaptive to various environments, according to Wang Yixin, an engineer with CRSC Research & Design Institute Group Co., Ltd. "It can completely replace human labor and improve inspection efficiency," Wang said.

The robot has been deployed in substations in Urumqi, capital of northwest China's Xinjiang Uygur Autonomous Region, which is susceptible to extreme weather such as sandstorms, heavy rainfalls and extreme low temperatures.

A single robot can inspect up to 1,000 pieces of electrical equipment in a large substation.

A staff member demonstrates a smart inspection robot at the 2019 China International Rail Transit and Equipment Manufacturing Industry Expo in Changsha, central China's Hunan Province, Oct. 19, 2019. [Photo/Xinhua]

On Saturday, a comprehensive industrial base for the R&D and testing of rail transit equipment was launched in Changsha.

The base, owned by China Railway Construction Heavy Industry Co., Ltd. (CRCHI), covers an area of 4,200 square meters and has four multifunctional test lines, including a test line for medium-low-speed magnetically levitated (maglev) trains.

"With the launch of more state-of-the-art products, China's rail industry has grown into the global frontrunner over the years," said Liu Feixiang, CRCHI's chief scientist. "We will introduce more innovative products in the future."